Sakamura Machine Co.,Ltd.

Sakamura Machine Co., Ltd. has established in 1959, and now Sakamura group is consisting of 11 companies for designing, manufacturing & after – service of cold & hot formers and the forging tools as well as producing and supplying the forged products to customers.

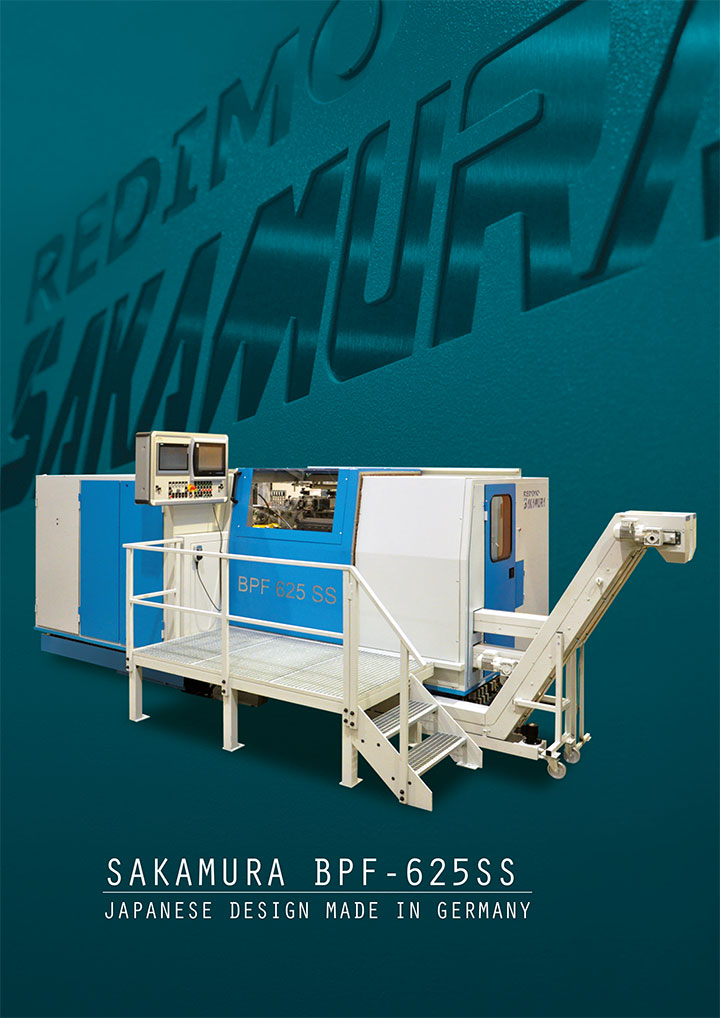

Japanese Design – Made in Germany

BPF-625SS – A machine designed to satisfy customers‘ demands

In 2011 we, Redimo and Sakamura, did a market analysis together with our customers to find out what the market and finally the customers want.

This led to a machine concept corresponding not only to the personal demands, but also to the mechanical and technical needs in combination with an environmentally responsible use of resources like e.g. energy sufficiency.

Based on the Sakamura design and taking into account the customers’ demands resulting from the daily use of the machine, a machine was generated whose components are mostly produced in Europe and mounted at Redimo in Willich. This gives the customer the possibility to interfere actively in the design of the machine during the mounting. As far as the components are concerned, a high value was set on the only use of European producers in order to allow a harmonization of the spare parts kept in stock at customers‘ works.

Today lots of our customers are facing the following problem: They buy a machine. This machine is CE-conform. But what about the whole unity of the process, i.e. all the single components like uncoiler, inline wire drawer, turning charger, etc. In cooperation with well-known producers we included the a.m. peripheral equipment into our risk assessment and are now in a position to declare the whole unity CE-conform.

The machine has six forging stations and one modified CS-transfer. The transfer has seven transfer cassettes while the last transfer cassette takes the forging part out of the sixth forging station and lays it down properly on the SP-conveyor. This kind of taking over protects the forging part against damages caused by the fall down of the forging part on the normal chute.

Another new development is the high speed cut-off system for precise cut-offs in combination with the patented hydro-pneumatic linear feeding system. The use of the wire end for production is standard.

For supporting the changeover, the feed length as well as the ejector spindles are adjustable by servo motors. A jog dial making a slow movement (jogging) of the forging ram possible helps the machine operator during the set-up of the transfer fingers and the timing of closing and opening.

All information needed like position and measurements referring to the tools can be stored in a modern tool administration.

The a.m. features can only be realized by a modern control conception. The heart of the control system (Profinet) is a Siemens Simatic S7-319 Safety Integrated with all necessary digital and analog I/Os as well as a Profibus/Net Master interface.

An energy management system integrated into the control system continuously supervises the energy consumption and switches off – depending on the mode – those drives which are not needed. Concerning the main drives and the auxiliary drives which for sure fulfil the energy efficiency class 2, we found a solution which should meet the demands regarding the reasonable handling of resources.

The main motor is controlled by an AC converter, brand ABB, with brake module, Profinet interface and motion control functionality, the servo motors, brand T + R Encodrive by an AC converter, brand Siemens.

We are convinced that this machine does not only fulfil our customers‘ demands, but also the requirements of modern technics and finally the rules of the labor protection.